Products

Home > Products > Harmonic Filter > Harmonic reactor(DC CHOKE)

Features

- International grade certificate:We have passed the ISO9001:2015 certificate , and we believe the certificate speak for themselves.

- Ferrite core:Adopted the permalloy laminations,and we are able to design various air gap accordingly that can have the best performance in harmonic compensation

- Winding:Adopted the H class(180℃ or more higher) that certificated by UL can insulate ferrite core well,and also adopted the same class of insulation tape and resin .And electrical insulation of coil to coil and coil to ferrite core can reach more than 4000 Vrms( 5600 Vp-p) that can provide the maximum impact strength for reactor while shortage

- Insulating paper:Adopt the H class insulating paper(180℃ or more higher)

- Accessories:The coil is installed on ferrite core or installed in EI silicon steel plate,and inside fill up with epoxy resin that make sure the mechanical strength and minimize noise

- Minimize design:We offer more flexible installment,and the wide choice of our product that can satisfy our customer

Specification

- Standard capacity:From 0.75 HP to 750 HP

- Optional standard impedance:1.5%, 3%, 5%(rated current) or other special impedance

- System voltage range:600 Voltage grade,50/60 Hz (208-600 Volt)

- Insulation system:H class(180℃ or more better)

- Rated current:From 2 to 950 Amps

- Continuous current:Must withstand the basic wave and the harmonic current

- Coefficient of induction curve:While in 0%~150% of current,the inductance value is 100%.And in 350%of current,the minimum inductance value is 50%

- Induction of tolerance:+/- 10%,turn of winding(zero tolerance)

- Maximum switching frequency:20 KHZ。

- Dielectirc:4000Vrms。

- Maximum of ambient temperature:45 °C。

- Temperature rise:H class insulation system(180 °C) and the maximum temperature rise is 115 °C

- IGBT protection:16,000 Volt /µsec (dv/dt rated),switching frequency(Maximum 20 KHz)

- Maximum altitude:1000 M。

- Protection:Open type or casing type

Others

We fully understand that the requirement of high precision equipment with high reliability and well design is the key of competitiveness,and we endeavour in offering the best stability and efficiency of converter control system while operating .Because those problems of current and voltage distortion will cause the damage to power equipment and precision equipment,we can offer you the best solution project of any converter and power equipment problem.

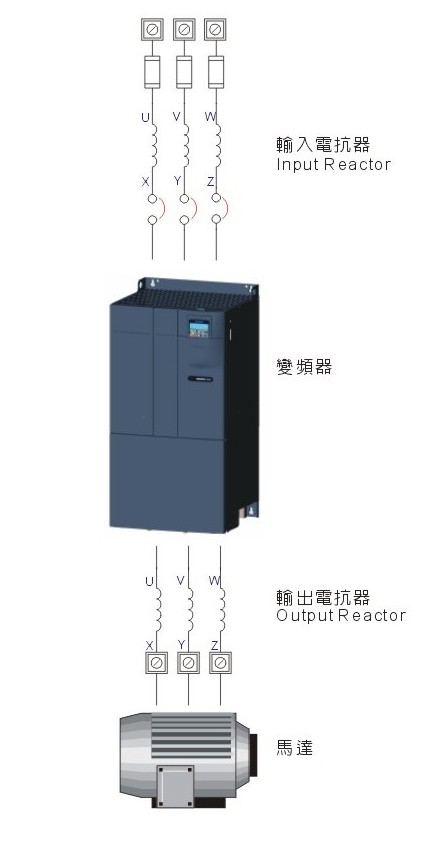

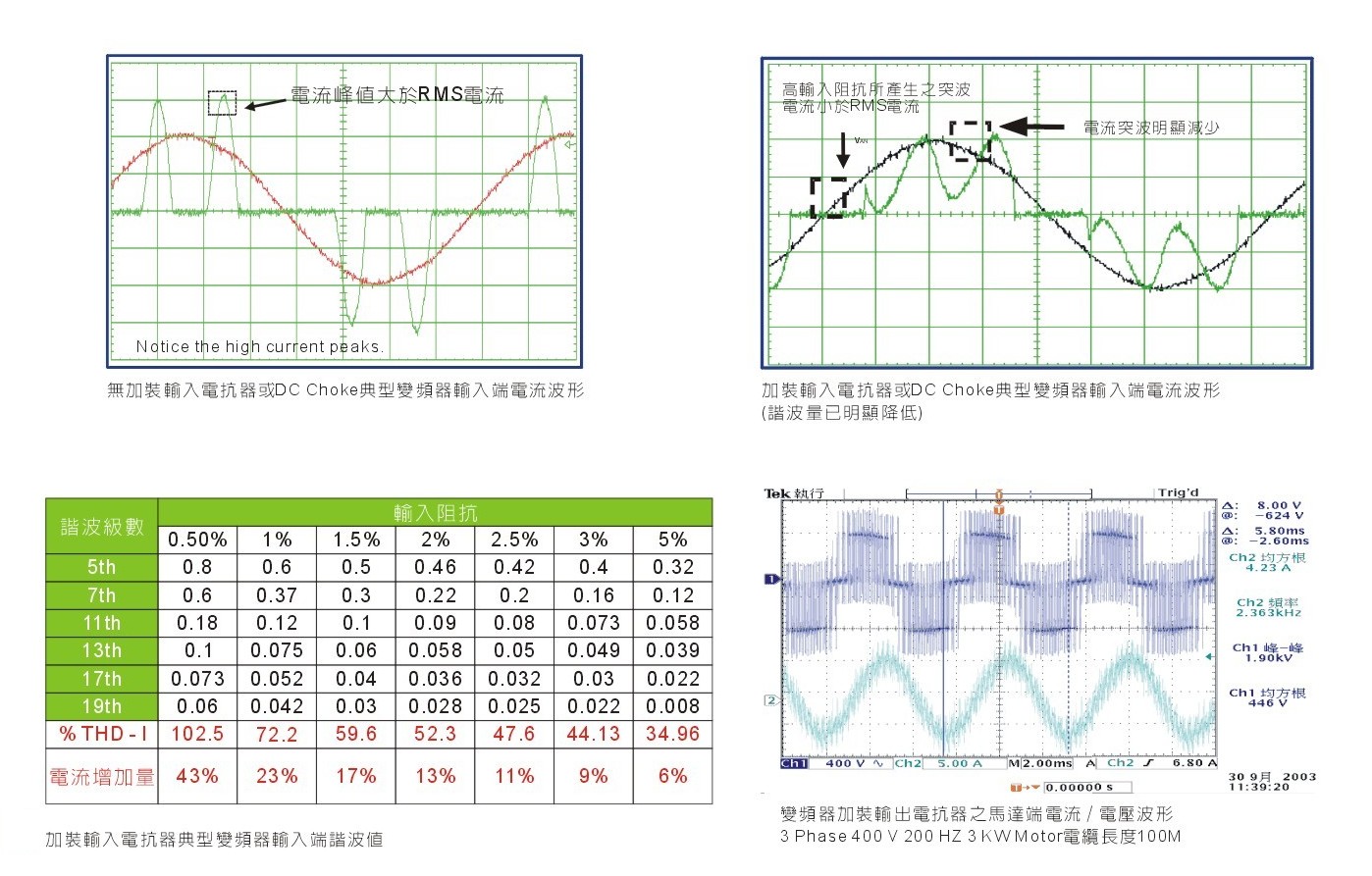

Our harmonic improvement reactor can apply in the input and output side of converter and can protect your motor and converter from those electrical interference problems .Those outstanding advantages can reduce the loss from shutdown and enhance productivity,and can have those advantages:

Our harmonic improvement reactor can apply in the input and output side of converter and can protect your motor and converter from those electrical interference problems .Those outstanding advantages can reduce the loss from shutdown and enhance productivity,and can have those advantages:

- Input current harmonic attenuation and reduce harmonic distortion

- Improve the active power

- Reduce the inrush current and current spike from circuit

- Reduce the dv/dt spike

- Reduce the peak voltage from motor

- Reduce the tripping of the converter and breaker

- Improve the reliability of the motor drive system

- Reduce the shot down period of the motor drive system

- Prolong the duration of motor and transistor

- Reduce the temperature and noise from motor